Silk Stockings

|

Silk Gartered Stockings RHT

Available: Jet Black or Suntan Sizes: 1, 2, 3, 4, 5 |

ALEXIS4U

| GUARANTEE | SIZING | GLOSSARY | SHIPPING | PACKAGING | CURRENCY CONVERTER |

|

|

Silk Stockings

|

|

Silk Stay Up StockingsRHT

Available: Jet Black, Barely There, White and Ivory Sizes: 1, 2, 3, 4, 5

|

|

Full Fashion Silk Stockings Charleston by CERVIN

Sizes: 1 (XS), 2 (S), 3 (M), 4 (L), 5 (XL), 6 (2XL), 7 (3XL) SOLD OUT $89.99 / Pair

|

Size chart is a reference as it can not allow for: Length of leg, Width of Thigh, Width of Calf and Width of foot

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

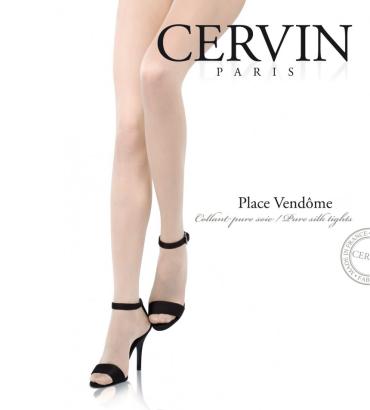

Place Vendome 30 Silk Pantyhose

Black Nude and Ivory are on back order Sizes: 1, 2, 3, 4 (S, M, L, XL) All Sold Out Pantyhose is a non returnable item |

Silk Pantyhose

SOLD OUT

$69.99

Pantyhose is a non returnable item |

|

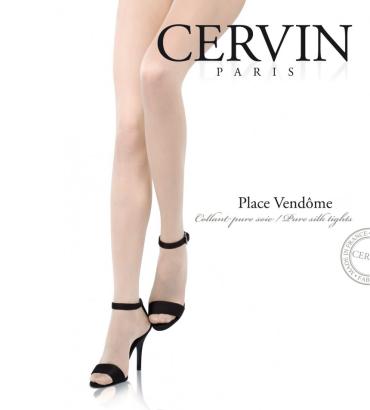

Place Vendome 15 Silk Pantyhose

Available: Nude Very Limited Supply Sizes: 5/6 (L / XL) Only Sizes 1/2, 3/4, (S / M, M / L) Sold Out Pantyhose is a non returnable item |

Silk Pantyhose

SOLD OUT

$69.99

Pantyhose is a non returnable item

|

|

Silk Stockings

|

||

|

Production of Silk

|

||

|

LIFE OF THE SILK WORM

|

||

| The production of silk is a lengthy process, from the birth

of the silk worm to the retrieval of the silk from the cocoon. The text

below gives a brief insight as to what is a basic example of how silk is

produced to enable the manufacturing the stunning pure silk stockings. The "Bombyx Mori" is the species of silk worm which produces the majority of silk for knitting and weaving. It is the white Mulberry which provides the silk worm the raw material in which to produce the silk. When the mulberry begins to bud, the eggs of last years silk moths, which have been hibernated during the winter months are brought into the mulberry districts and slowly warmed. Warming is often achieved by ladies carrying small packets of eggs about their persons, but a stove lamp is often used as a modern alternative. A graduate advance in temperature from 10º to 24ºC over a period of 10 to 14 days is required to effect a uniform hatching. The eggs are little larger than a pin head when the caterpillar emerges, but feeding constantly on the mulberry leaf, it out grows its skin 4 times in as many weeks. After the fourth and last molt, the worm continues to eat and becomes quite ugly and fat between 7 and 10 centimeters long. In this last stage it will actually consume about 4 times the weight of leaf he has consumed to date, so some 36000 worms hatched from an ounce of eggs, which should eventually produce at least 5.5Kg of raw silk and eat as much as a ton of foliage, one acre may produce 3 to 4 tons of leaf for a return of 22.5Kg of raw silk. When the worm stops eating, it looks for a location to build it's cocoon, twigs or straw are provided and soon he will begin to produce a filament silk in to a cocoon, working until he is wrapped inside, to later emerge as a moth. To produce silk, this process has to be interrupted, as the birth of a moth causes destruction of the cocoon, as it secretes brown gum to dissolve the cocoon. So before the emergence of the moth the chrysalis is put to sleep by exposure to the sun, or hot air, but this process makes it increasingly difficult to unwind the cocoon filament in the process known as reeling. |

|

REELING |

||

|

Through two glands in it's head the silk worm emits the

filament silk know as a "bave" the reeling process consists in finding the

end of this bave, unraveling it and winding it in to a hank. Raw silk is

quite a gummy/sticky substance, so before separating the filaments the

cocoons must be softened by immersion in hot water to loosen the gum. The

cocoons are placed together in a basin of near boiling water, which starts

to dissolve the gum, once the gum is dissolving the cocoon filaments adhere

to a small brush or rod which rotates the water. The outside layer of the

cocoon is thrown away as imperfect after sticking to the rod, these

discarded portions are known as "knubbs". Now the cocoons are ready for

reeling, the size or denier of a single cocoon being too fine to be of any

commercial use, it must be decided how many cocoons need to be reeled to

make one single yarn. When these filaments are boiled and reeled together in

one single process the naked eye will not be able to determine that this

single thread is actually made of many filaments. To ensure uniformity, the

threads are run through a systems of pulleys to make for example a

yarn of 3 denier, |

||

|

Article Copyright © 2002 Belle Hosiery

|